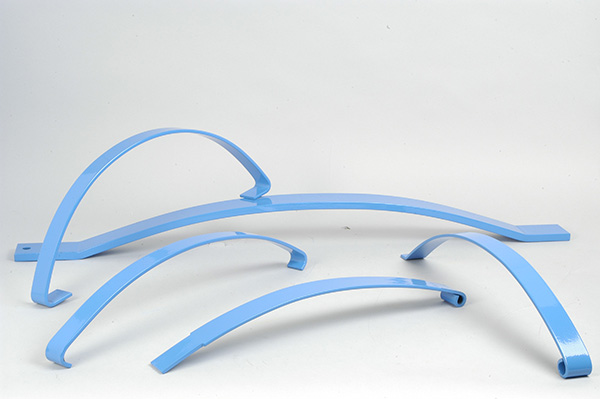

We produce a wide and complete range of leaf springs, symmetrical and asymmetrical parabolic and trapezoidal, with various eye geometries.

The materials used are steels that are compliant with the standards UNI EN 10089-2006 with profiles according to the standard EN 10092. The type of steel is chosen depending on the section of the suspension element.

The leaves of the springs, after being rolled, forged and formed, undergo thermal processing treatment to obtain the desired mechanical properties.

The subsequent shot peening treatment increases their life span, countering fatigue. Coatings are used for surface protection.